PLEASE CLICK ON A CATEGORY BELOW TO FIND WHAT YOU ARE LOOKING FOR:

Welcome to SHELIX Helical Cutter Heads Distribution

Are you spending too much money on replacement knives for your planer and jointer?

The original SHELIX HEAD by BYRD TOOL offers you the following advantages:

- Extreme noise reduction (1)

- Chip outs are virtually eliminated (2)

- Your dust collection system works better (3)

- Necessary replacements of knives cost a fraction in most cases (4)

- Knives are made from carbide which will last you up to 40 times longer (5)

- Replacing knives is easy and doesn’t require alignment (6)

(Check bottom of page for further explanations)

We currently offer SHELIX heads for 620+ different planers and jointers and additionally, 50+ different models for shapers and moulders. If you have a machine that is not listed on this website, we still offer a SHELIX head in most cases (there are some machines on the market for which we cannot offer a SHELIX head). Please inquire.

Upgrade to a SHELIX Helical Spiral Cutter Head today and forget about replacing knives for a looong time! All insert knives in a SHELIX Head are sharpened on all four edges. When one edge becomes dull, simply rotate the knife insert and continue producing saw dust! There is no need for adjusting any knives as you needed to do with your old head. These inserts fit right into their spot! Best of all, the inserts are made from carbide which means that each single edge per insert will last you a lot longer than your old steel knives. They will also allow you to run a piece of man-made material (such as MDF) through your machine without damaging the knives!

Let's do the math: We dare to say that for as long as you continue to work with natural woods, each edge per knife insert will last you at least 10 times as long as your old steel knives. (depending on the wood species you use, you may even expect up to 20 times as long). Each knife insert has four sharpened edges, so in actual fact, these knives will last you at least through 40 cycles of re-sharpening and/or replacing your steel knives. You know best what you had to spend on money and time to replace or re-sharpen your steel knives, so do the math and you will soon realize that a SHELIX head might be more expensive than replacing your knives, but in the long run, it will save you! And last, consider this: In many cases, steel knives need replacement not because the whole knife is dull but an enclosed rock or nail in the wood has caused a chip in the knife which now leaves ugly marks on the wood. If this happens with a SHELIX head, you still have three more sharp edges per knife and if you need to finally replace knives, it is usually only one or two of them that are affected. They come in a box of 10 pieces that cost you $35.95!

Woodworkers know that a shear cut is far better than a straight cut. You also know that a stagger cut is much better than just a single straight knife and is a lot easier on your dust collection system. If you just happen to plane a nail or staple, it is not necessary to replace expensive knives the full length of your planer head. All individual knives are sharpened on all four edges and a simple rotation is all you need to do and your knives cut like new again. These knives are made from carbide and one single edge will perform much longer than standard steel blades. They even allow you to run a piece of MDF through your machine. Only after all four edges are worn out, replace only the affected small inexpensive knives and you are ready to go. You might expect to pay a small fortune for a journal head with these features, but at Byrd Tool Corp., we can manufacture a journal head to your specifications for typically a fraction of the cost you might expect.

Explanations:

- Extreme noise reduction

When you think of the straight knives in your original cutter head, they work just like a fan that moves air at very high speeds. This is what is causing the high noise levels when no wood is passing through the machine. With a SHELIX helical cutterhead, the knives are only 15mm (about ½” wide) and the air movement caused by each individual knife causes so much less noise that even the addition of all knives doesn’t generate as much noise as one straight knife. When you plane a 10 inch wide board for example, the traditional straight knives will cut these 10 inches straight off which also causes a high noise level. Because of the spiral pattern, a SHELIX head will remove only 15mm (about ½ inch) at any given time, causing a decreased noise level. While the noise level reduction is measurable in db, we cannot put a general number on it as it depends on your machine and many factors (width of the machine, number of straight knives, RPM’s etc.) However, many people report a noise reduction of up to 50%. - Chip outs are virtually eliminated

Chip-outs are the number one problem for many woodworkers when it comes to planing wood. Especially some hardwoods such as Maple always tend to show small holes in the surface after the wood went through the planer or over the jointer. This is caused by the straight knives when they start to become dull as the wood sometimes offers such density that the knives no longer cut but break or actually tear wood chips out of the surface. Many spiral cutter heads on the market reduce this problem as only small single knives cut the wood at any given time but this is where the Byrd SHELIX head makes all the difference: The knives are sitting on a diagonal angle on the head and therefore, offer a SHEAR cut instead of a straight cut. This SHEAR cut virtually eliminates chip outs. - Your dust collection system works better

When you are cutting a 10 inch wide board in your planer with a standard cutter head, you create 10 inch wide wood chips that your dust collection system has to suck up. The Byrd SHELIX head only cuts 15mm (about ½ inch) at any given time and therefore, the wood chips are much smaller. Smaller wood chips are much lighter in weight which is why your dust collection system sucks them up much easier. - Necessary replacements of knives cost a fraction in most cases

When knives become dull, you have to re-sharpen or to replace them. In actual fact, most replacements become necessary when a hidden nail or rock in the wood chips out your knives and they now leave ugly and uneven patterns in the wood. When this happens with a Byrd SHELIX head, usually only one or 2 small knives are affected. As the knives are sharp on all four edges, a simple turn of 90 degrees solves the problem without a knife replacement. - Knives are made from carbide which will last you up to 40 times longer

Our C3 carbide lasts an average of 10 times longer than traditional steel knives, never mind that they allow you to also cut man made materials such as MDF and plywood. As all knives are sharp on all four edges, a simple turn of 90 degrees eliminates the need for a knife re-sharpening or replacement. Therefore, these carbide knives will last you about 40 times longer than steel knives. These little insert knives cannot be re-sharpened and once they become dull on all four edges, a replacement becomes necessary. If you were used to re-sharpen your steel knives on average 2 times before replacing them, this means by now, you would have already paid for 13 sets of knives and 26 re-sharpening’s (never mind the time you saved). - Replacing knives is easy and doesn’t require alignment

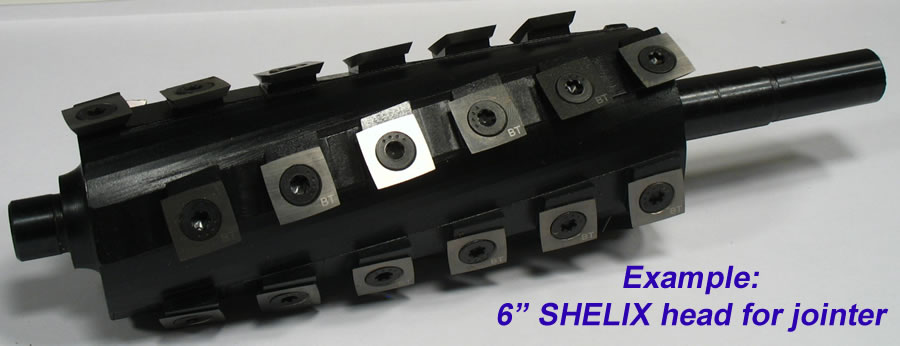

As you can see in the picture above, all knives are fastened with a screw through a hole in the center of the knife. The knives are sitting in a matching pocket that keeps the knife in perfect alignment. When installing new knives, simply let the screw guide the knife into the correct spot.